|

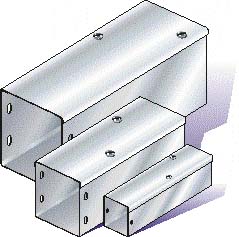

3.1- Standard Trunking

Return Edge Cable Trunking complies with Bs4678 part 1 class 3, and

manufactured from prime hot-dipped galvanized sheet steel to

a number of standard sizes and can be epoxy painted to

customerís color specification. Available in 2M or 2.44M

standard lengths, the trunking is supplied complete with

covers. However, many variations and options are available

upon request.

Tinned copper earth continuity links are also Supplied.

3.2-

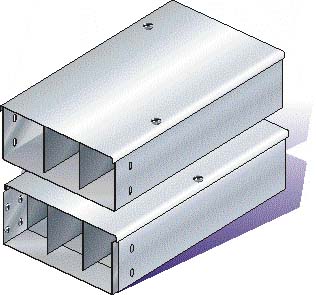

Multi compartment trunking:

Multi compartment trunking based

on standard sizes is produced to order.

When unequal compartments are required, the trunking can be

manufactured to customer precise specification. Partitions

are spot-welded into position to produce the necessary

compartments.

3.3-

QUICK RELEASE TURNBUCKLE

Installation is both simple and

fast as trunking covers are normally supplied with quick

release turnbuckles which require only a quarter turn to

lock or release. The turnbuckle is a two piece component

comprising of an alloy die cast button and carbon steel

pawl. Fitting a new turnbuckle requires no special tools and

is simply a matter of drilling a 8mm diameter hole. Fitting

the turnbuckle and tapping down the turnbuckle locking pin.

3.4-

SCREW FIX

Trunking Return Edges are fixed with captive nuts to ensure wires

protection from cover screws.

3.

5- MULTI COMPARTMENT TRUNKING

The part number of multi

compartment system will exactly the same of single

compartment except adding number of compartment at the end

of the code n

Unless otherwise requested by

the customer, the multi compartment will be divided equally

of the width.

3.6- Cable capacities of standard trunking

|

|

Conductor Size Sq.mm |

|

Trunking

size |

1.0 |

1.5 |

2.5 |

4.0 |

6.0 |

10.0 |

16.0 |

25.0 |

35.0 |

50.0 |

70.0 |

95.0 |

|

50 x

50 |

138 |

132 |

98 |

67 |

52 |

33 |

24 |

16 |

12 |

9 |

7 |

5 |

|

75 x

50 |

208 |

185 |

148 |

101 |

79 |

51 |

37 |

24 |

18 |

13 |

10 |

7 |

|

75 x

75 |

312 |

278 |

221 |

152 |

118 |

76 |

655 |

37 |

28 |

20 |

16 |

11 |

|

100 x

50 |

277 |

247 |

197 |

135 |

95 |

67 |

49 |

39 |

25 |

18 |

14 |

10 |

|

100 x

75 |

516 |

370 |

296 |

203 |

158 |

101 |

74 |

49 |

37 |

27 |

21 |

15 |

|

100 x

100 |

555 |

484 |

394 |

271 |

211 |

135 |

98 |

66 |

50 |

37 |

28 |

21 |

|

150 x

50 |

416 |

370 |

296 |

203 |

158 |

101 |

74 |

49 |

37 |

27 |

21 |

15 |

|

150 x

75 |

624 |

556 |

443 |

304 |

237 |

152 |

111 |

74 |

56 |

41 |

32 |

24 |

|

150 x

100 |

833 |

741 |

592 |

406 |

316 |

203 |

148 |

99 |

75 |

55 |

42 |

31 |

|

150 x

150 |

1250 |

1112 |

888 |

409 |

475 |

305 |

222 |

145 |

112 |

83 |

54 |

47 |

|

|

|

3.7-

Accessories:

Standard fittings are

supplied with captive nuts for covers. Each type of

accessories has a common coding such as M99 for 90 deg.

Gussett Bend. The use of suffix /T /I /O denotes the lid

fixing position. Components M99/T can therefore be

incorporated into a complete coding as M99/T/5050.

1- Bends & Tees

|

|

|

|

Cover

on top |

Cover

on inside |

Cover

on outside |

|

90deg

Bend

|

|

|

|

|

90deg

Gusset Bend

|

|

|

|

|

45deg

Bend

|

|

|

|

|

Tee-piece

|

|

|

|

|

Gusset

Tee-piece

|

|

|

|

2-

Sockets Outlet Plates:

Socket outlet punching can be

supplied in short cover sections for trunking widths of

100mm and above. Please specify trunking width A and use

suffix /G or /P to complete component finish references. The

single socket outlet plate accepts the most commonly used

power and telephone outlets. Plates can be made to order to

suit special requirements.

Single

socket outlet or telephone

Twin socket outlet

3- Offsets

When ordering offsets,

specify dimensions l or H as well as size of trunking. When

ordering reducers, use both component sizes in reference.

|

M11/V Vertical offset |

M11/H Horizontal offset |

M 34 Reducer |

|

M 45 Crosspiece |

M 20 Standard

"Fish Plate" connector |

M 22 Standard

connector |

|

M 24 Smooth bore bush |

M 33 Block end |

M 44 Flanged connector |

|

| |

|

|

|

4-

Bridge piece arrangement

Where the use of flyover is too restrictive, the bridge

piece offers an easy solution for cable separation.

3.8- Under

Floor Trunking:

3.8.1- Under floor Trunking:

The under screed trucking

system is manufacture from galvanized sheet steel to BS

2989. The system has been designed to comply the

requirements BS 4678 part 2.

Service outlet and junction boxes are designed to be

installed at predetermined position to provide the end user

with Power, Telephone, Data etc.

Standard trunking is supplied in 2 or 2.44 mtr length and

available in a choice of 2, 3, or 4 compartments.

Elbow, Tee, Cross Junction boxes are fabricated from

pre-galvanized sheet steel to BS 2989 same as trunking. The

thickness of the trunking body is 1.0mm and cover 1.2mm.

Tinned copper earth links are provided for every joint as

per request.

Ease Installation and convenience of final user have been

considered as priorities in our design.

Moreover, custom designed and manufactured items are

available to meet special site conditions.

The Trunking is totally buried

in the Floor Screed and available in various depths to suit

most cable capacity requirements. The systems junction boxes

and service outlet units are installed flush with

surrounding floor area. Our systems ensure maximum

flexibility and convenience for the end user.

3.8.1.a.

Under floor trunking includes the following product range:

1. Metal Trunking

2. Joint/fix Connector

3. 90 Deg. Junction Box

4. 3-way Junction Box

5. 4-way Junction Box

6. 90 Deg. Riser Bend

7. Service Outlet Box

8.Hinged Lid Assembly

9. Conduit Connector

10. Stop End

3.8.1.b.

Accessories:

The Junction boxes incorporates

partitions for straight or angle and flyovers assembly for

tee and cross units as required. Standard depth of all

250x250mm square junction boxes are 65mm including strong

and light weight aluminum reversible lid, to meet carpet

thickness, and surrounding frame.

Standard 65mm deep junction boxes are suitable to accept up

to 225x38mm under floor trunking.

Junction boxes with increased depth are also available to

meet different screed levels.

Junction boxes to accept wider than 225mm trunking are

supplied with 3mm thick steel epoxy finish lids and

surrounding frame.

1.

Tee

2.

90 Deg. Angle

3.

4

Way Cross

4.

Riser bend

5.

Service Outlet Box:

Galvanized steel base box is

supplied with fixed partitions to meet the required number

of compartments. Numerous configurations are available

within 3 or 4 compartments to meet and install different

combinations of wiring accessories of British, European and

American standard. Standard 65mm deep boxes are suitable to

accept unto 225x38mm under floor trunking. Through and

Termination type service outlet boxes with increased depth

other than 65mm are also available to meet different screed

levels.

A.

Through Type

B.

Termination Type

6.

Hinged Lid Assembly

Final hinged lid

assembly is high quality lid and trim molding. Tray lid is

reinforced with 4mm thick galvanized sheet steel and has a

8mm thick carpet infill. Hinged lid assembly is fixed after

installation of service outlet box.

Dual quick fix securing clamps reduce installation time to

minimum. The lid position allows the simple selection of

self closing, vertical parking for installation and

maintenance, access and removal for changing the lid opening

direction.

Cable retainers are fixed as standard for safe and

convenient cable routing through cable exit outlets.

Lid loading test shows no permanent deflection when

subjected to a load of 2,.5kn applied via a 25mm square

indenter.

3.8.2Uunder

Floor PVC Ducting

Under floor UPVC ductings are

high impact, heavy gauge and trapezoidal shaped. Non

corrosive ducting is light weight and can be easily cut with

hand tools at site during installation. Ductings and

accessories are available in three profiles in matt white

finish.

|

|

|

|

|

|

|

|

|

Jointing Sleeve |

|

50 x 25 |

75 x 25 |

100 x 25 |

|

|

|

|

Accessories

All accessories are suitable to

accept single profiles of 25mm high uPVC ducts to make the

number of compartment as required. Standard 3 compartment

with 60mm screed depth of Junction boxes, service outlet

units and other accessories are supplied. Please specify

your required screed depth other than 60mm screed

1.

4 Way Cross & Tee

2. 90 Deg. Angle

3. Service Outlets

4. Riser bend

5. Fixing Clips

|